WD (Weight Distribution) hitches have been around for a long time and can be an asset when towing large or heavily loaded trailers. Designed for use with bumper pulled trailers (the name used for all trailers connected to a hitch behind the rear axle) or RV trailers. WD hitches come in many different configurations and can offer additional features like sway control or tongue weight gauges. Let’s touch on why you would want a WD hitch, the advantages and disadvantages of different designs, and how to pick the correct WD hitch for your application.

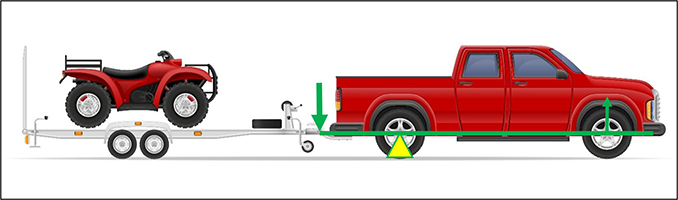

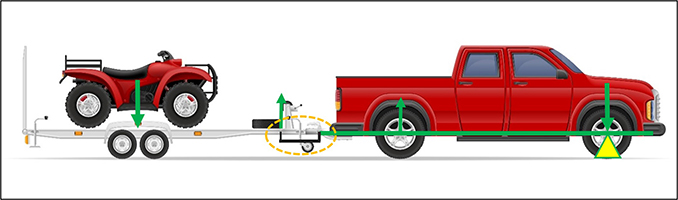

First, we need to explain the purpose of the WD hitch to understand why it can be an advantage when towing. When you’re towing a trailer with a standard rear hitch, the tongue weight of the trailer presses down on the trailer ball, which acts like a tetter totter with the rear axle as the pivot. As the trailer presses down, weight is placed on the rear truck axle and removed from the front steering axle. This is not a problem with small trailers with moderate trailer loads up to about 4000 pounds. Bigger trailers, heavily loaded trailers, and RV trailers all have heavier tongue weights and can cause adverse handling in the tow rig. The last thing you want to do when hauling large loads is decrease the weight on your steer axle. Which is why larger trailers are often built as goose neck or 5th wheel versions, which places the tongue weight in front of the tow vehicle rear axle, thereby putting weight on both axles. Goose neck and 5th wheel designs typically pull better and are more stable, but require a truck set with those hitch designs. Bumper pull trailers are more common and are generally more versatile for many people.

Weight distribution hitches have spring steel arms that extend back behind the trailer ball that attach to the trailer using chains or bars. These arms work like the handles of a wheel barrel when attached to the trailer. They “lift” up on the back of the truck hitch, transferring some of the tongue weight to the front of the tow vehicle and back onto the trailer axles. Linking the truck and trailer together as one plane. They help level out the tow vehicle and provide more stability and control by transferring the weight better across the whole vehicle and trailer assembly. Many of the WD hitch designs also incorporate some sway control, which helps reduce your trailer “wagging” its tail as you travel. This is very helpful when towing RV trailers and long trailers.

There are three different designs in WD hitches, but all of them serve the same purpose. Each of them have advantages and disadvantages. Read on and see what will work best for you and your application.

Round Bar WD Hitch

Advantages

- Lower cost – Generally less than other designs.

- Lighter weight – Lighter than trunnion bar designs.

- Better ground clearance – Better ground clearance compared to other designs.

- Easy adjustment – Easy to set up and adjust for occasional users.

Disadvantages

- Limited weight capacity – Usually limited to trailers less than 10,000 lbs.

- Less durable – Round bars may wear faster with heavy use.

- Noisy – Round bar designs can make noise when turning or when driving over uneven terrain.

Trunnion Bar WD Hitch

Advantages

- Higher weight capacity – Trunnion bar hitches can handle heavier trailers up to 15,000 lbs.

- Durability – Trunnion bars are robust and better suited for frequent or heavy towing.

- Better sway control – Many trunnion systems have integrated sway control systems.

- Smooth operation – Usually they are quieter and more stable compared to round bar designs.

Disadvantages

- Higher cost – They typically cost more than round bar designs.

- Heavier – Most trunnion systems are quite heavy.

- Clearance issues – Trunnion systems sit lower than other designs.

Andersen WD Hitch

Advantages

- Lightweight – Unique design uses chains, friction, and bushings to provide weight distribution instead of bars.

- Quiet operation – Anderson hitches operate very quietly.

- Quick installation – Quick to set up and remove. Ideal for travelers that remove their trailers frequently while traveling.

- Effective sway control – Due to the design they are great at minimizing trailer sway.

Disadvantages

- Limited weight capacity – Best suited for trailers under 10,000 lbs.

- Less adjustable – They work best on trailers with a consistent operational weight.

- Chain wear – Chains may need replacement from heavy use.

Picking the correct WD hitch starts with knowing the weight of what you’re towing and calculating the tongue weight. The best method I know is to go to a local truck scale. Follow these steps to find your overall trailer weight and tongue weight.

- Weigh the tow vehicle without the trailer. Record the front axle, rear axle, and total weights.

- Connect your loaded trailer to your tow vehicle with a standard ball hitch. It is important to weigh RV trailers loaded and set up as you will be towing them to get accurate weights for determining the correct WD hitch.

- Weigh the complete vehicle and trailer. Record the tow vehicle front axle and rear axle weights. Record the trailer axle(s) weight.

- Subtract the loaded rear axle weight from the empty rear axle weight. This is your approximate tongue weight. Ideally, the tongue weight should be about 10-15% of the overall trailer weight.

- Subtract the empty weight of the front axle from the loaded weight of the front axle. Record the difference for the next step.

- Add the calculated tongue weight to the trailer axle weight and subtract the front axle weight difference. This is your approximate loaded trailer weight.

- For example, I have a 2001 Chevy Suburban that weighs a total of 7,320 pounds. 3,800 lbs. on the front axle and 3,520 lbs. on the rear axle. With my 35’ empty car trailer attached the weights are as follows: Front axle 3,480 lbs., rear axle 4,780 lbs., and the trailer axles are 3,680 lbs. Total combined weight of 11,940 lbs. Take the loaded rear axle 4,780 lbs. – empty rear axle weight 3,520 lbs. = 1,260 lbs. trailer tongue weight. Then take the front axle empty 3,800 lbs. – loaded 3,480 lbs. = 320 lbs. weight removed front the front axle due to the teeter totter effect. Finally add the tongue weight 1,260 lbs. + the trailer axle weight 3,680 lbs. – front axle difference 320 lbs. = 4,620 total trailer weight. The other way to calculate trailer weight is to take the total weight of the truck and trailer 11,940 lbs. – the total vehicle weight 7,320 lbs.= 4,620 lbs. total trailer weight. The important factor here is to note the 320 lbs. change in the front axle weight, which translates to reduced vehicle control and handling.

Look for a WD hitch that is equal to or slightly above the total weight of your loaded trailer and taking into account the tongue weight of the trailer. Research the different designs and find one that best fits the frame of your trailer. Consider incorporating sway control on all trailers 20’ or longer length. For the best performance, follow the manufacturer’s instructions carefully when setting up your WD hitch. Check YouTube because many of the hitch manufacturers have videos about how to properly set up their WD hitches.

WD hitches can cost between $500-1,700 depending on the application, design, and weight rating. The heavier the trailer, the more the hitch costs. Is a WD hitch worth the extra expense? In my opinion, most definitely, yes! A properly set up WD hitch eliminates or greatly reduces the challenges of towing heavy or long trailers. They reduce the strain on the tow vehicle rear axle and improve vehicle control and ride quality by balancing the weight across all axles and tires. Personally, I use a WD hitch with any trailer over 15’ weighing 4000 lbs. and up. I even prefer it on the empty single place car trailer to reduce the bouncing going down the road. Trailers pull so much better using a WD hitch that I really don’t want to pull them without it, especially on long trips.