VVT (Variable Valve Timing) and VVL (Variable Valve Lift) Systems

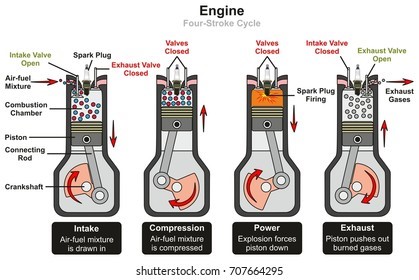

Many modern vehicle manufacturers incorporate VVT (Variable Valve Timing) and/or VVL (Variable Valve Lift) systems in their engines to gain maximum fuel efficiency while maintaining power output and smooth engine operation. To understand how this technology benefits the driver, we need to understand the basics of engine operation. A vehicle engine is essentially an air pump that controls the explosion from a fuel/air mixture and transfers the explosion energy into rotating movement. Thus, propelling the vehicle forward. Nearly all vehicle engines use the four stroke, Otto engine design. See illustration. The valves control the flow of air/fuel into the cylinder and the exhaust out of the cylinder once the combustion process takes place. They must be timed to open and close at precisely the correct points of crankshaft rotation to maintain engine operation. If they get out of sync the engine will cease to run or run very poorly. For example, a broken timing belt or chain will leave you stranded with a non-running vehicle.

VVT and VVL systems manipulate when the valves open, when the valves close, and how far the valves open. Remember to think of an engine as an air pump. The more air/fuel charge that can be drawn into the combustion chamber (cylinder) with each intake stroke of the engine, the more power the engine will produce. This is why we see manufacturers using turbocharged engines more often. Turbos pack more fuel and air into the combustion chamber with each stroke. Thereby producing more power from a smaller engine.

Timing is the key to smooth engine operation. If the intake valve opens too late your fuel/air charge will not be enough to allow the engine to build power. If the intake valve opens too soon, the piston will push exhaust gases back into the intake manifold. This will result in power loss and poor engine running. The precise timing between the valves operation and crankshaft rotation is the key to maximizing engine efficiency and power output.

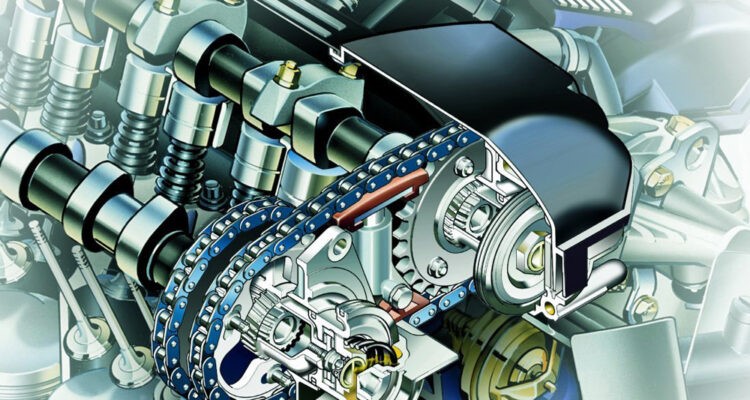

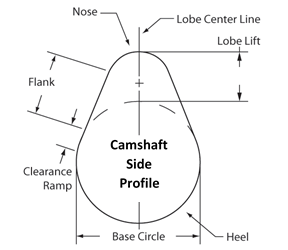

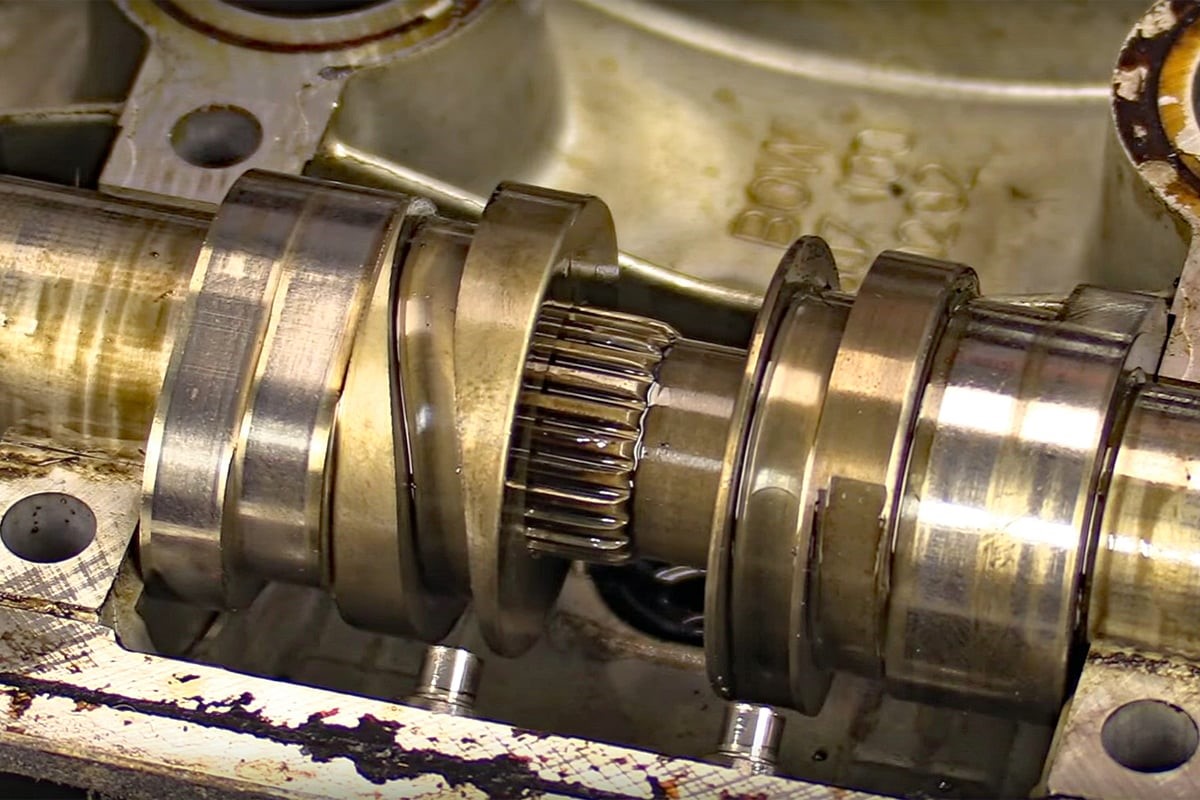

Valve operation is controlled by the rotation of the camshaft(s). The lobes on the camshaft raise the lifters, which transfers that movement to the valves through the valve train. How long the valve is open and how far it opens is due to the design and shape of the camshaft lobes. VVT systems change the camshaft to crankshaft timing using a variable timing gear. The PCM (Powertrain Control Module) monitors the camshaft position and adjusts it using engine oil pressure as needed. Depending on the engine RPM (Revolutions Per Minute) and engine load. At high RPM the intake valve closing is delayed gaining the benefit of high intake air velocity entering the cylinder. More air and fuel in the cylinder = more power. We can’t have the intake valve closing late at low RPM because it causes engine running issues. VVT systems allow the PCM to adjust the valve timing as needed depending on the operating conditions. This allows the engine to run smoothly at low RPM with good torque while taking advantage of the power gains that can be had at higher engine RPMs. The best of both worlds.

VVL systems change the camshaft lobe profile. Which changes the valve duration (how long the valve is open) and valve lift. This is usually accomplished by shifting camshaft sections that are controlled by the PCM using actuators. The camshaft sections shift back and forth between two different cam lobe profiles that the camshaft followers are rolling on. It comes down to engine RPM and load. At low engine speeds the valve does not need to open as far. Less air, less fuel = increased fuel economy.

Both VVT and VVL engines are designed to provide the power the driver wants with the fuel economy of a smaller, more efficient engine. Engine manufacturers are constantly working to improve engine efficiency and fuel economy in order to meet ever tightening government standards. We are already seeing many engines with direct injection and cylinder deactivation technology in addition to VVT and VVL systems. All these advanced engine systems require stringent maintenance to keep them in top operating condition. The first of which is consistent and regular engine oil changes. Failure to do so can lead to high repair costs. Sometimes the simplest of things can make the biggest difference.

To see if your vehicle needs some quality maintenance give the experts at Sanderson Auto Repair a call today.

Aaron B.